We know the benefits and importance of waterproofing our fishing reels. Making a RTV Silicone Gasket is great idea for most parts like body, side-plate and now for roller clutch. The roller clutch is the one of the most important for this. In the previous article, I gave information about how we can provide waterproofing in the body area by using rtv silicone on our reel.

To view custom gasket I made for spinning reel body to improve its waterproofing see the article of How to properly make a custom gasket using RTV

What is RTV silicone : Room temperature vulcanizing silicone

What is the difference of RTV compared to Silicone : Stands for room temperature vulcanizing, cross-linked silicone, water repellent, rubber polymer, two-component, soft-medium of hardness available, useful for DIY projects.

In this article, we will learn how to protect the roller clutch mechanism from external factors. Roller clutch anti-reverse bearings, which are one of the places where water can reach the most easily, have functionality problems when they show the slightest signs of corrosion or rusting and need replacement.

This mechanism, located just below the rotor, is unprotected in many reels; Even if there is no wetting with water, humidity, especially saltwater, it can cause demage in this part with the salty moisture circulating actively in the air.

As you can see from the picture below, the clutch balls rusted out only one season of aggressively fishing in saltwater.

What is the Roller Clutch on Spinning reels

Clutch bearings prevents if the handle shaft rotated reverse direction like rotor, handle shaft and other equipments such as drive gear, pinion gear, worm gear etc.

Most of the spin reels have an on-off switch located in the body, which can move the balls to prevent or allow in reverse or forward direction for reel.

In this way, the springs apply compress or loosen the balls so that the roller can rotate only in the normal direction or both in the normal and reverse direction.

When the switch is closed, the reel moves only in the normal direction, while the mechanism prevents it from moving in the reverse direction. Thus, when the reel is under load (for example, when a fish on), even if you do not hold the handle, since the springs in the mechanism will already press on the balls, so the reel does not back-play, because of the reverse rotation is locked.

If the switch is open, the springs will release the compress on the balls and the roller will move freely in both the normal and reverse directions, even under load.

Roller Clutch Anti-Reverse Maintenance

As with all moving parts, keeping it clean and maintenance is very important. If the roller clutch is damaged like other moving parts and loses its function in this case; your reel may move in reverse direction even switch is off, slipping, excessive back-play or completely lose its functions.

DO NOT USE GREASE FOR THIS PART. If you use grease instead of synthetic oil, the function may be lost and slipping or back-play may occur.

Common Roller Clutch Failures

If rust, wear or corrosion has occurred on the outer layers of the balls or bearing shaft, slipping and noise may occur.

If the springs are exceeds the elastic limit or wear, back-play and noisy may occur.

If there is noisy operation while the rotor is moving in the normal direction, there may be low viscosity oil, dust-dirty, wear or damage to the shaft bearing. In cases of wear or damage, replacement is required. Otherwise, it must be cleaned and lubricated.

If there was no problem before the servicing but there was a slipping after the periodic maintenance, you probably have the springs or the balls and clutch cage installed incorrectly. In addition, the viscosity of the oil you use may be very low and may cause slipping. In this case, consider using a heavier synthetic oil.

Types of Silicone Gasket for Roller Clutch

There are two types of custom silicone gasket we can made for it. Fully covered gasket or half covered gasket. We will describe in this article “Improved Version” as fully covered model and for half covered will called as “Simple”.

Simple Silicone Gasket For Roller Clutch

As described above, you learned how important this mechanism is. Now we will make a simple custom gasket for the roller clutch with RTV silicone gasket maker. Thus, the roller clutch will be protected from external factors, and unwanted dirt, dust, grease and water from under the rotor will be prevented into the clutch bearing.

Here is the requirements to custom silicone gasket for roller clutch:

1. RTV silicone gasket maker

2. Non-stick oily baking paper or stretch film

3. Packing tape

4. Scissors

If you want you may use a stretch film only without additionally wrap a baking paper. Add a little oil or grease before applying the rtv silicone for easy removal.

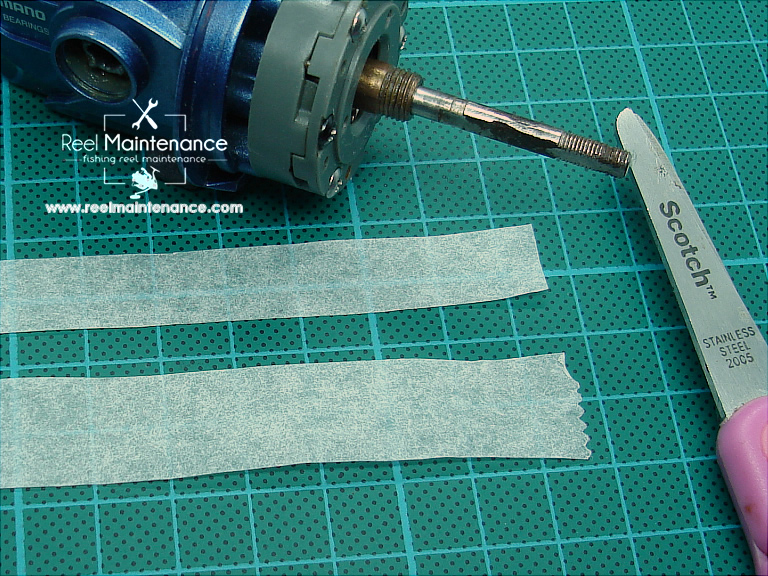

Cut the baking paper with scissors according to the roller clutch dimensions on your reel.

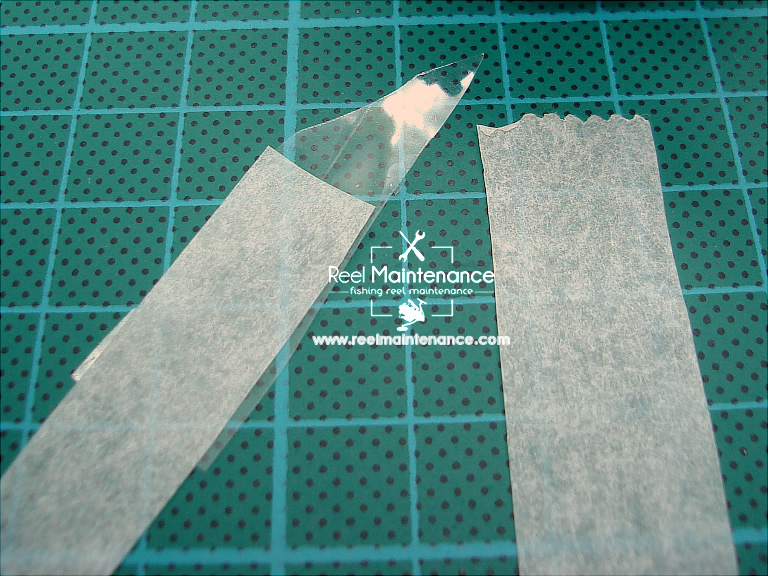

Cut a small piece of packing tape and stick it on the end of the baking paper.

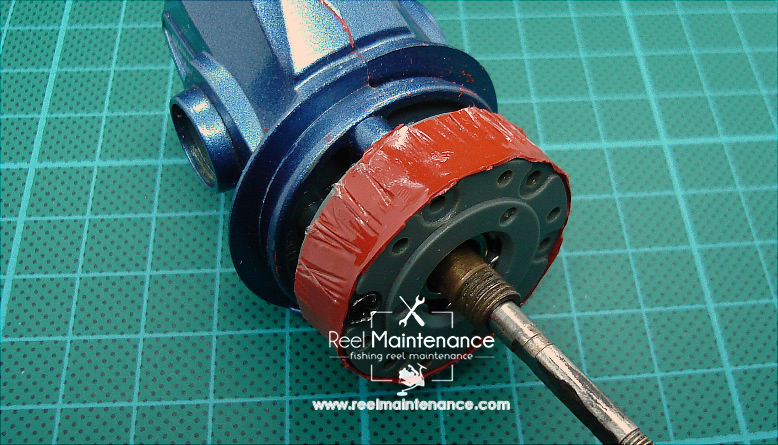

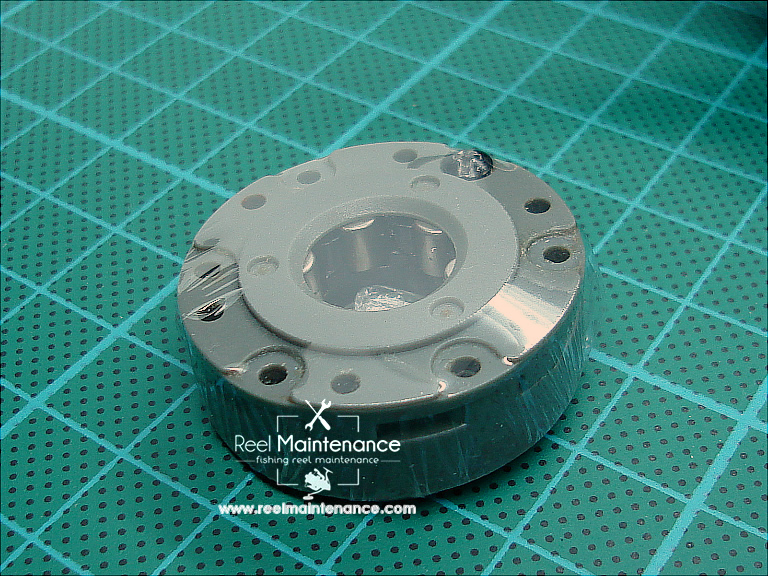

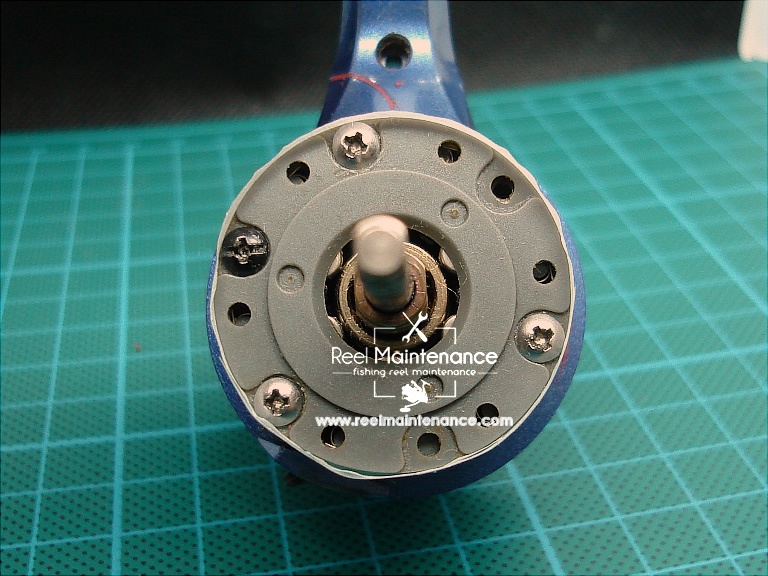

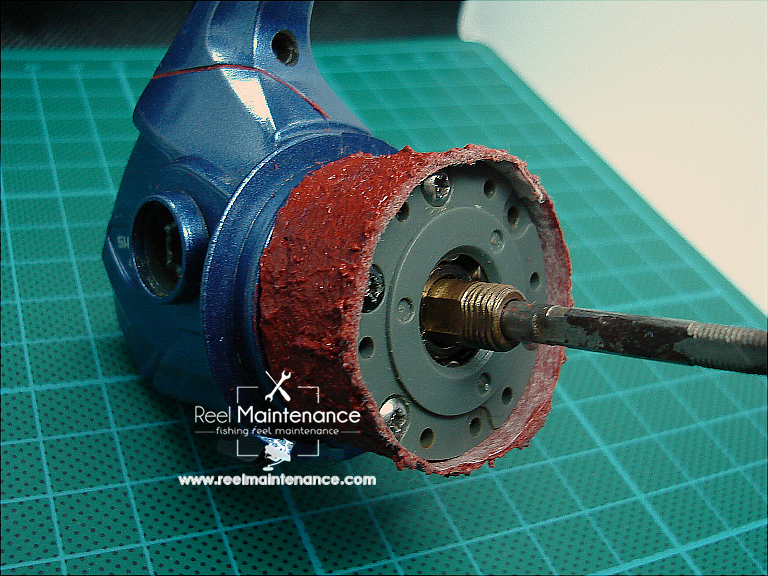

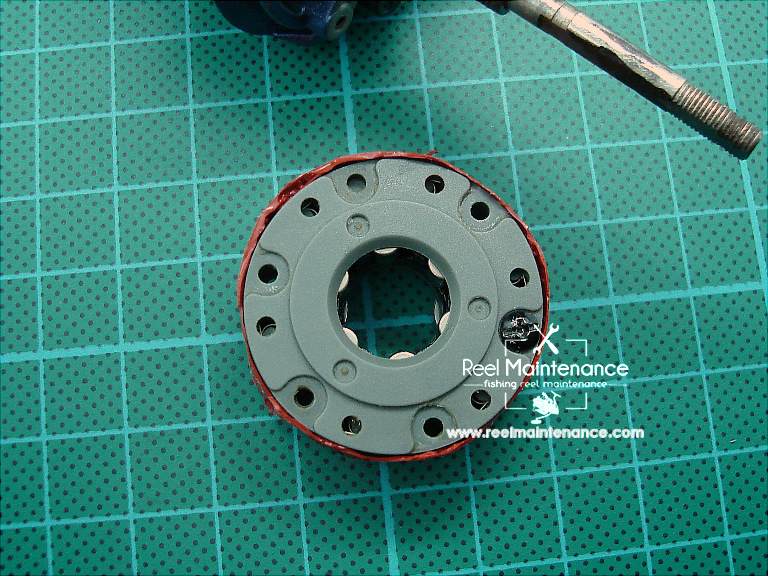

Not required but use a stretch film first before the cooking paper if you any worries for overflow. To do this, remove the roller clutch from body by unscrewing three of screws.

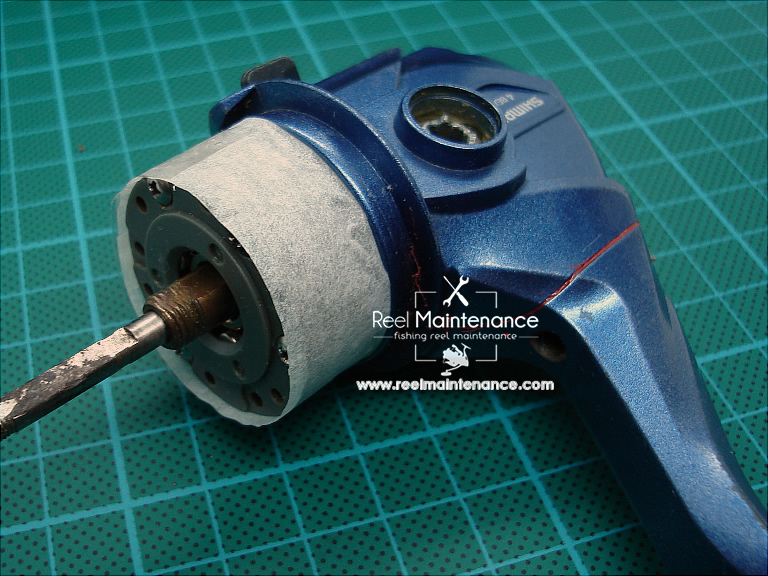

Than wrap it with stretch film and go to next step.

Wrap the baking paper tightly around the roller clutch and stick it with tape on the other piece.

Ensure that the baking paper or stretch film should be tightly wrapped so that there is no any gap between roller clutch and your custom mould.

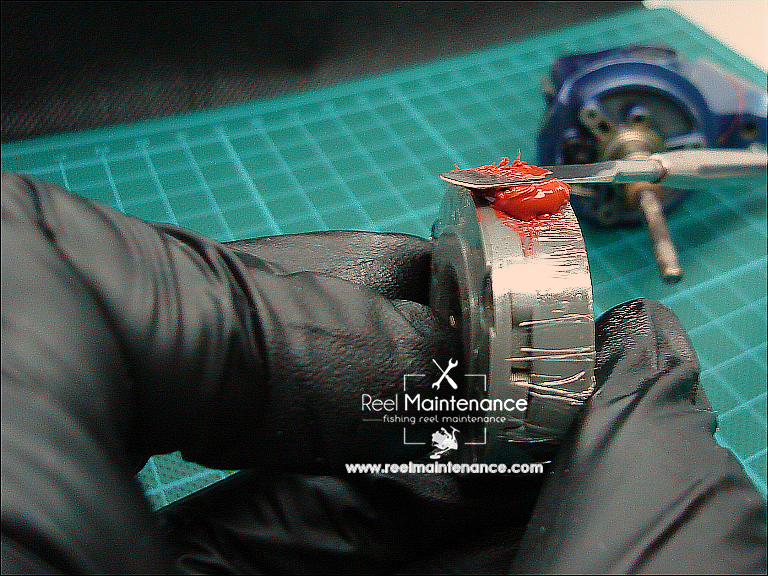

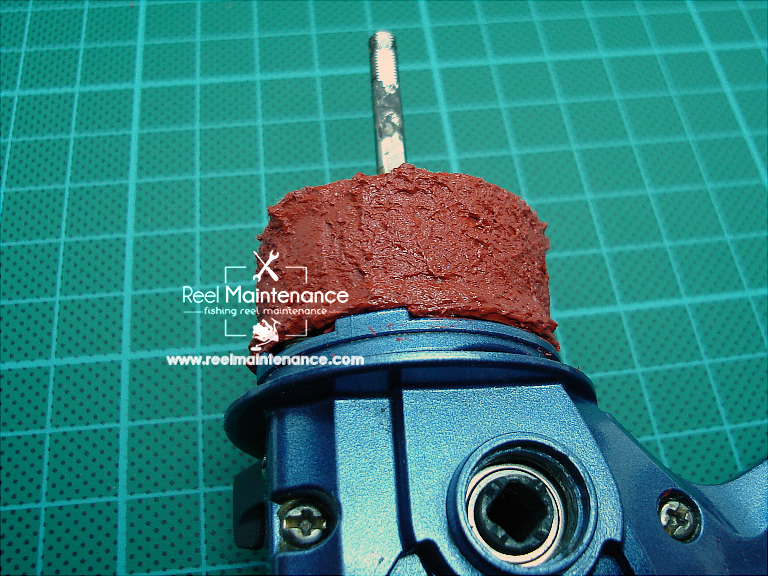

Fill the 5cc (5mL) of syringe with rtv silicone

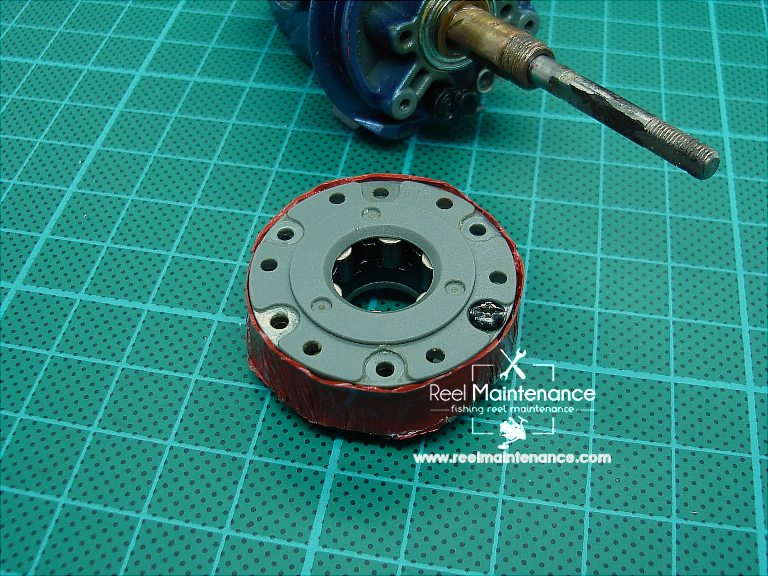

Apply RTV silicone gasket maker.

An aesthetic appearance doesn’t need to be smooth, it might even be better if you make a textured surface.

Because the texture on the bottom layer will be shiny, it may slip but the textured surface will stick, so when our gasket is dried and ready for use, we will reverse and assemble it so that the textured surface is on the mechanism, that’s what we want.

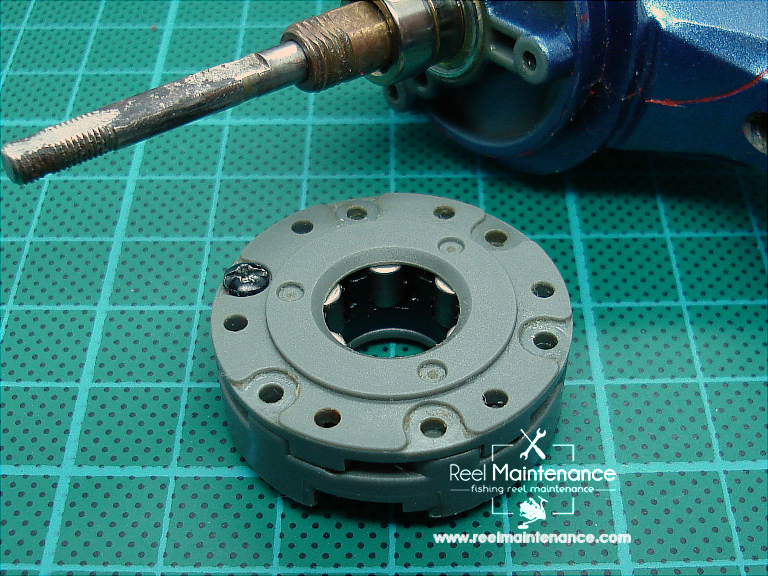

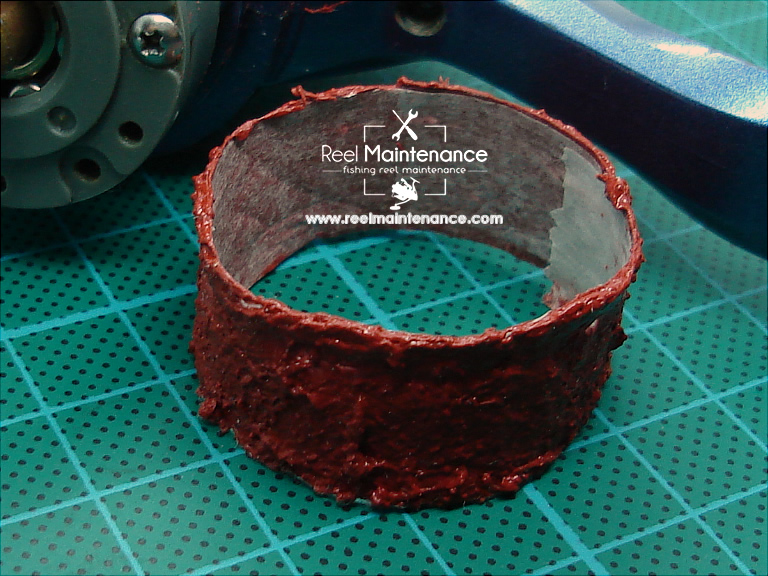

We made removable gasket. After curing time is out you could lift out the dried gasket from the roller clutch to removing a paper mould.

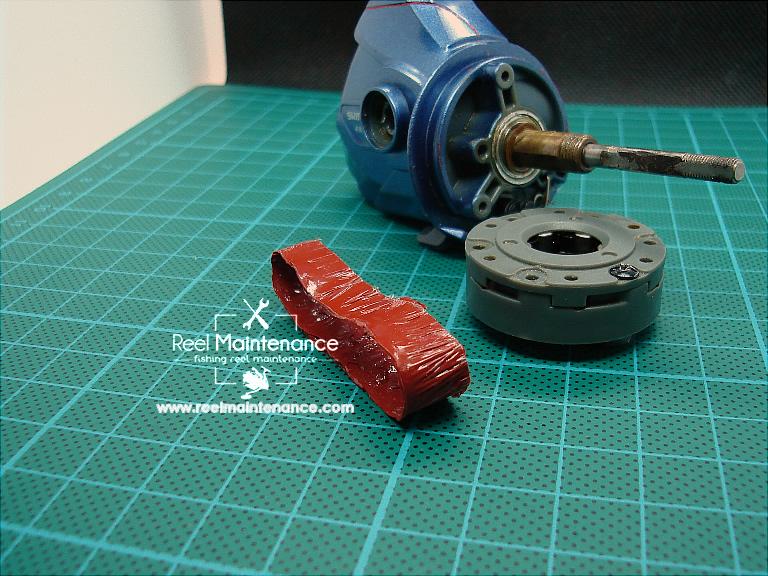

You can remove the paper mould.

Gasket is ready to use. Reverse the textured part before the use so that it will remains on the inside. This will provide to gasket will grip finely the entire surface. Than, assemble it to roller clutch.

Tips for RTV Silicone Gasket

If you want a textured design on surface of gasket, wait first for 15-30 minutes after applied. Than, you could made your custom texture easily.

There is no need too much silicone. Use a little and make a thin structure of silicone gasket as much as possible. Thick material may increase the friction. Rotor will stopped to work if too thick material was created.

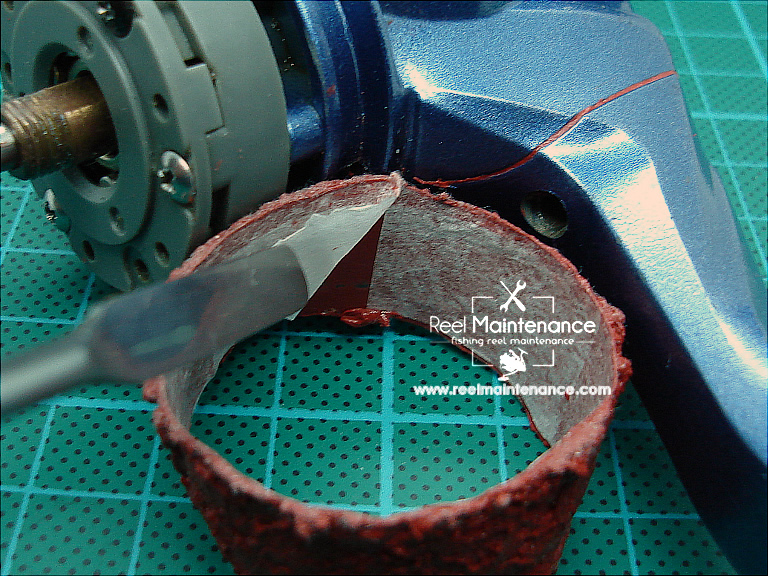

You can cut the excess or burr from the gasket easily with using a scissors after the dry.

Allow 24-36 hours for dry your custom made rtv sealant silicone before use. Do not remove the gasket from the mould during this time.

RTV silicones are heavy duty and very durable for external factors, even saltwater and UV rays. There is no need any servicing for your custom gasket. When completes its lifetime, re-apply the new one. That’s it.

Your custom gasket will last at least for 3-5 years while fishing in actively and normal usage without any problem.

If you see any hardening, cracking, matting or color changes in surface of your custom gasket, its time to need the replace it with new one.

Half of 5cc (5mL) syringe filled with RTV silicone is enough for making a simple roller clutch gasket.