Under normal circumstances, the special rtv silicone gasket type that surrounds the roller clutch mechanism, similar to the rubber buckle we made, described and called as “Simple” from another article is enough. In this way, we prevent saltwater that may come from under the rotor from entering the mechanism.

To view Simple model of gasket we made, tips for rtv silicone, common failures and what is the roller clutch and much more, I’ve added to first article. see the how to make a silicone gasket for roller clutch

However, sometimes in saltwater fishing, it may be possible for saltwater to reach the top of the mechanism and from there to the roller clutch bearing as a result of the sea being extremely choppy or the water hitting the reel body aggressively while fishing in extreme conditions. In this case, it is very easy to make a gasket that fully covers the roller clutch mechanism, which is a more improved model.

Sometimes there may be a water leak from the top of the rotor and this leak can reach the roller clutch mechanism. In general, in cases where there is no gasket support in the rotor nut, there are leaks, cracks or there is a gap between the nut and the rotor or the nut is loose, it is inevitable that the water will leak from here into the rotor and reach the roller clutch anti reverse.

The Parts Needed for Making an Improved Version of RTV Silicone Gasket:

1. RTV Gasket maker silicone

2. Hollow hole punch

3. Digital micrometer caliper

4. Synthetic grease (Not petreleum based)

5. Stretch film

6. Scissors

7. Cotton ear stick or synthetic brush

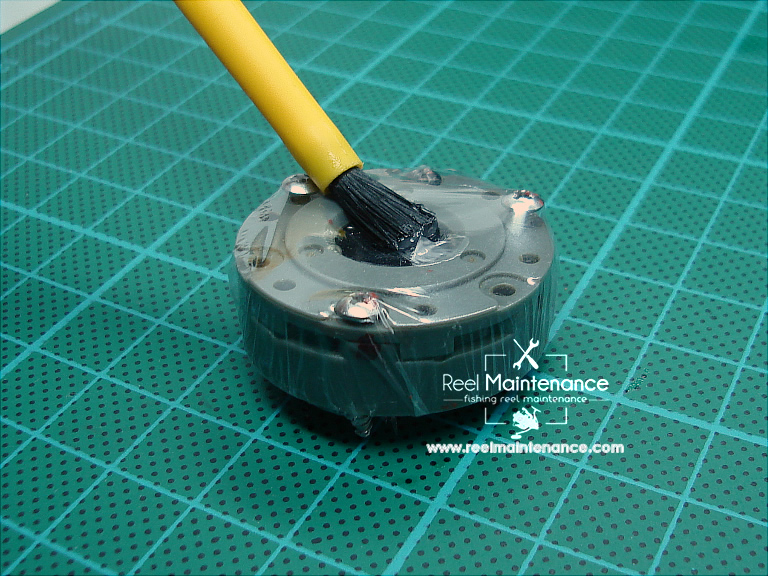

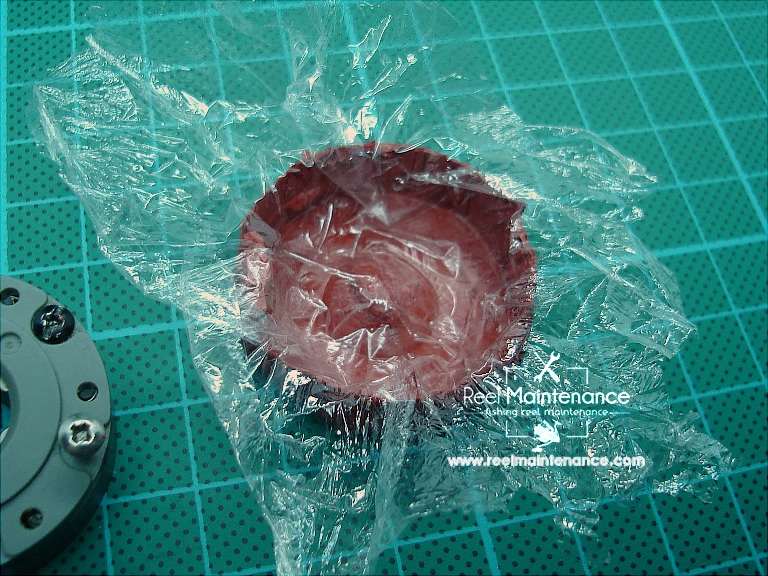

Cover with stretch the entire roller clutch mechanism. Thus, silicone does not leak into unwanted parts. Apply a small amount of synthetic grease with a brush or cotton swab to any area covered with stretch film. Do not remove the mounting screws, this will allow to create fine condition gasket like an excellent mould.

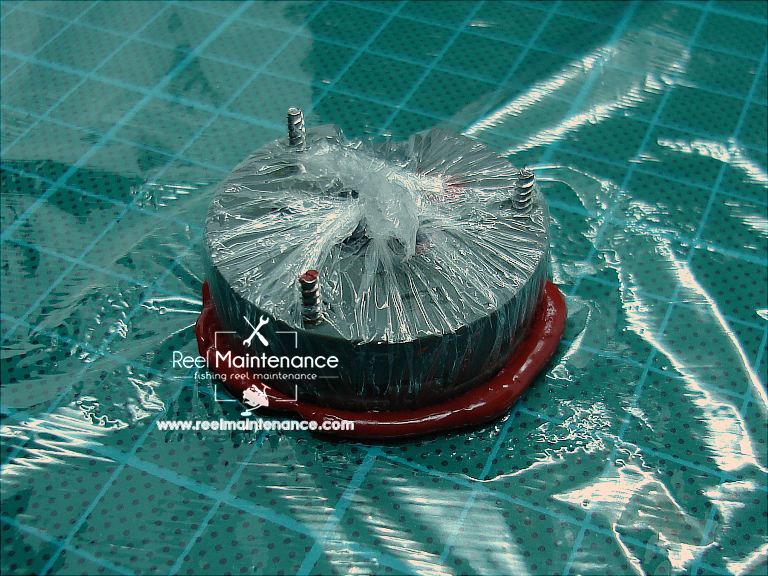

Grease the surface that will contact the silicone by cutting again with scissors from a second piece of stretch film.

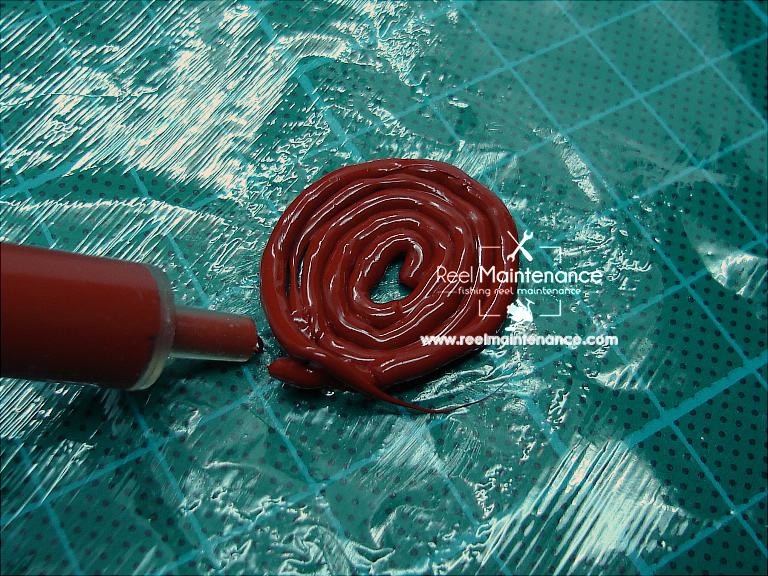

Roughly apply the RTV silicone to cover the surface of the stretch film. For improved model, 5mL of syringe fully filled with rtv silicone is needed.

Place the mechanism in reverse condition on the second piece of stretch film that you cut with scissors, greased and roughly applied the RTV silicone. In this way, the silicone will spread over the entire surface.

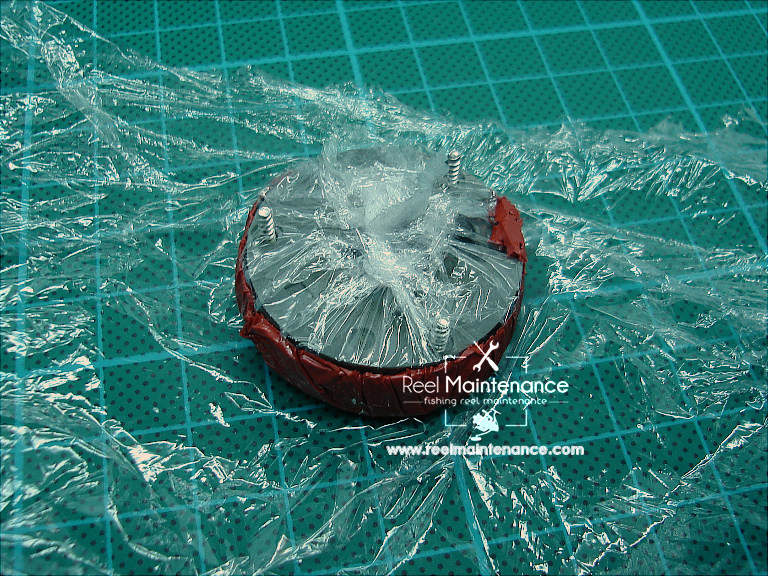

Then, collect the stretch film from the sides upwards like packing the mechanism and make sure that the silicone overflows to the sides and wraps the entire mechanism.

After making sure that the silicone covers the entire mechanism, let it dry for 24-36 hours.

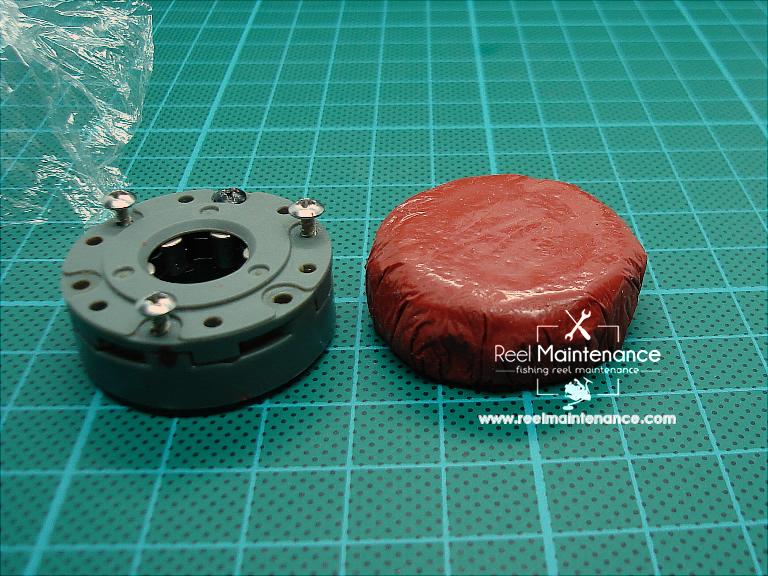

After the drying time is over, first separate the stretch film on the top layer from the silicone and remove from it.

Then remove the silicone from the stretch film on the inner layer.

The gasket has been removed from the mould and needs to drilling a hole.

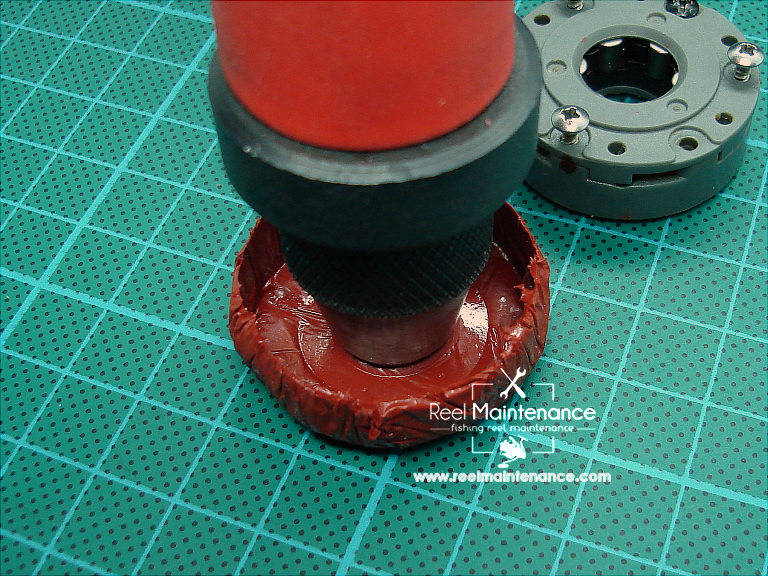

Now we will drill a hole where the rotor, pinion and shaft will fit. I will use hollow hole punch set for this.

I will use 13mm hollow punch to create a precise size.

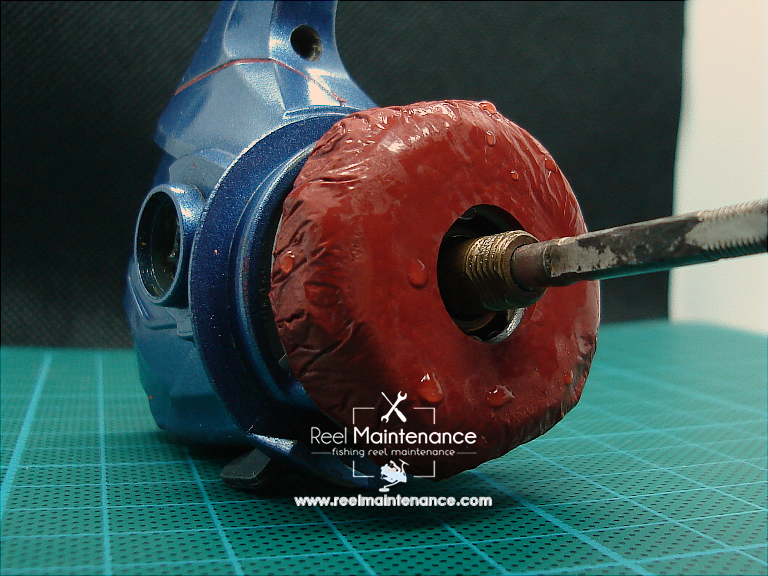

Looks great. You may mount the silicone gasket now to roller clutch anti-reverse.

The improved custom reel rtv silicone gasket is ready to use.

If you want before the mounting your gasket you may wash your custom rtv silicone gasket with liquid soap to clean up the grease we applied to stretch film as mould release oil to remove the custom gasket from mould easily.